Case Study

FMB Innovation: Pilot to Shelf-Ready

Flavor-forward FMB line developed, piloted, and scaled with compliant packaging.

Client

National Beverage Brand

Wanted an FMB line to extend portfolio reach with rapid seasonal drops.

Scope

R&D to Packaging

Pilot flavor builds, sensory, stability testing, and retail-ready packaging with coding.

Approach

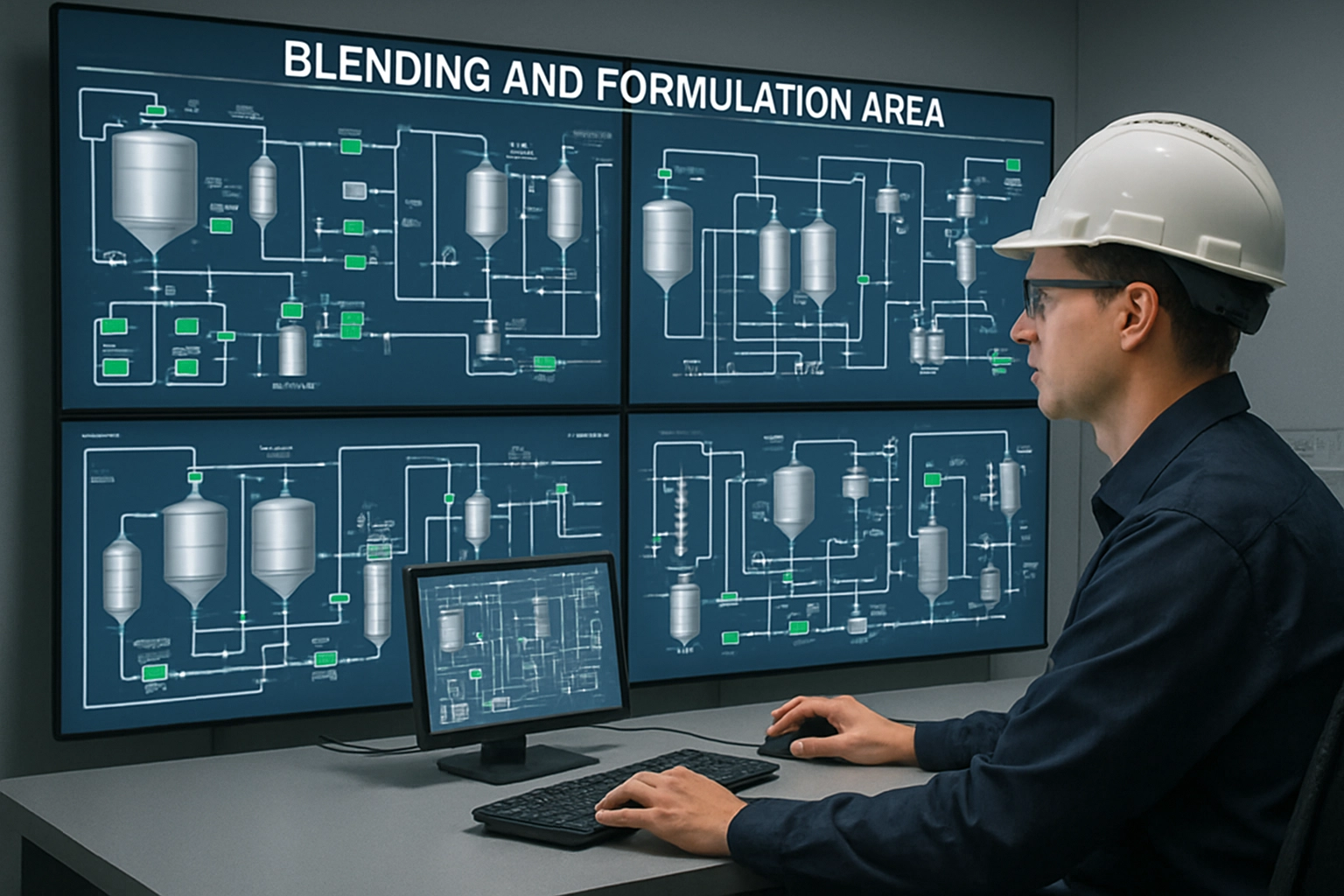

Precision Flavoring and Rapid Changeovers

We built a flavor system and packaging plan that kept SKUs distinct and on schedule.

- Inline flavor integration with dosing accuracy for multi-flavor variety packs.

- QA program for ABV, stability, and sensory across four SKUs.

- Canning with coding, UPC verification, and pallet standards for national retail.

4 SKUs

Launched simultaneously with consistent QA outcomes.

Low DO

Protected flavor and shelf life with low-oxygen canning.

On Shelf

Met retailer window with approved packaging and documentation.

Outcomes

Flavor Integrity and Retail Compliance

Documentation and packaging met buyer requirements; flavor matched pilot approvals.

- Approved by national buyers with coding and UPC validation.

- Retained samples and QA data shared for ongoing quality reviews.

- Reserved run slots for seasonal and promotional SKUs.