End-to-End Production Excellence

Brewing, blending, packaging, QA, and logistics engineered to deliver shelf-ready beverages at speed.

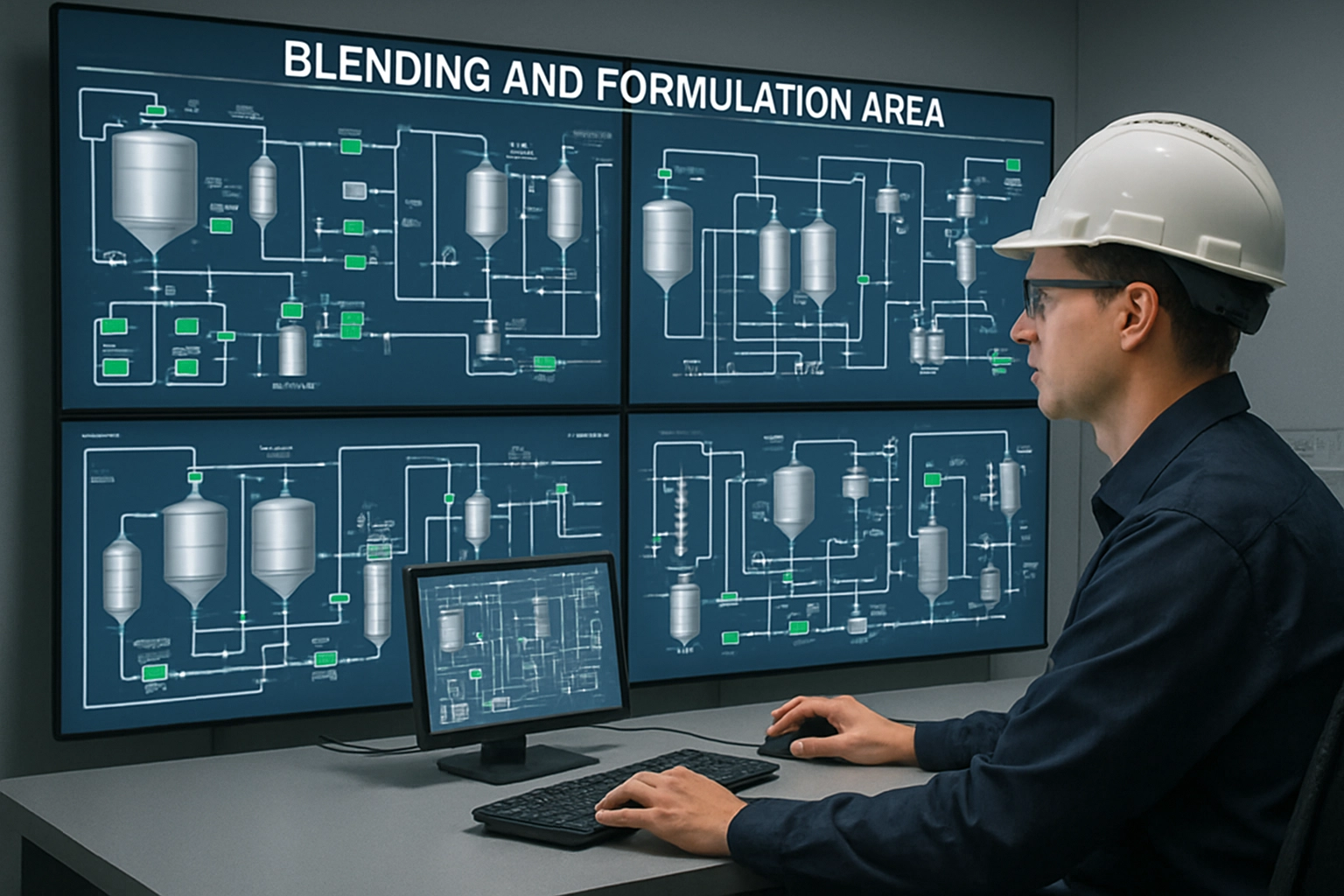

One Facility, Multiple Beverage Pathways

From raw material intake to finished goods, our lines are configured to protect flavor, carbonation, and stability across multiple beverage categories.

- Automated brewhouse and cellars for malt bases and craft styles.

- Precision blending for sugar, flavor, carbonation, and functional ingredients.

- High-speed, low-oxygen packaging for cans, bottles, and kegs.

Fermentation Excellence

Temperature-controlled fermentations, yeast management, and cellar capacity to support diverse malt beverages.

Formula Accuracy

Automated dosing and in-line mixing for consistent flavor delivery and carbonation targets.

Audit-Ready Quality

Micro, sensory, and stability testing with retained samples and full documentation.

Flexible Formats

Cans, bottles, kegs, and variety packs with seam checks, fill weights, and on-line inspection.

Integrated Logistics

Warehousing, inventory management, and outbound freight coordination for national programs.

Pilot & Scale

Lab-scale validation, pilot batching, and commercialization support for new SKUs.

Measured, Documented, and Traceable

Our Manufacturing Execution System (MES) connects production data, maintenance schedules, and QA checkpoints for every run.

- Live visibility into yields, downtime, and quality trends.

- Digital batch records with integrated lot tracing and changeovers.

- Preventative maintenance tied to production to minimize unplanned stops.

Bring Your Beverage to Life With KGM

Share your formulation, packaging needs, and launch timeline—we will configure the right line and schedule.