Premier Contract Beverage Manufacturing

From recipe development to shelf-ready products. Precision brewing, flexible packaging, and end-to-end quality built for modern brands.

Full-Service Manufacturing From R&D to Market Launch

KGM Manufacturing LLC is a Frisco, Texas-based partner for craft beer, hard seltzers, flavored malt beverages, and non-alcoholic innovations. We combine industrial-scale automation with a craft mindset to protect your flavor, speed, and compliance.

- Dedicated project teams covering formulation, QA, packaging engineering, and logistics.

- Integrated MES for real-time production data, predictive maintenance, and full batch traceability.

- Flexible production windows to support pilots, regional launches, and national rollouts.

Engineered for Precision, Speed, and Shelf Stability

Purpose-built lines for brewing, blending, packaging, and QA. Every run is documented and measured to protect your brand.

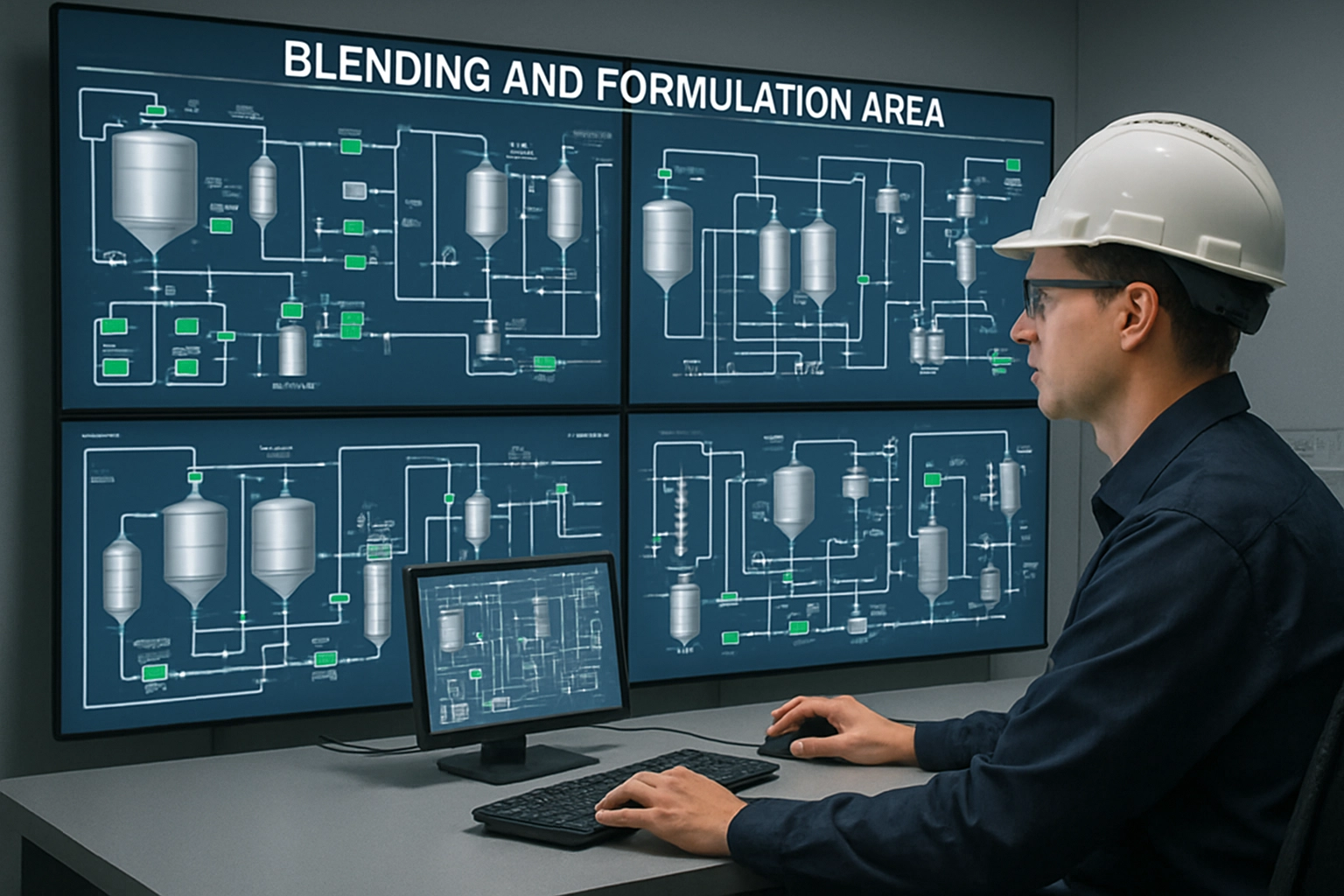

Formula-Perfect Integration

Automated batching for complex sugar, flavor, and carbonation profiles. MES-controlled for repeatability.

Explore Blending

High-Volume Cellars

Clean, controlled fermentations for malt bases and craft styles with 24/7 monitored cellar operations.

Brewing Details

50+ Tests per Batch

Micro, sensory, and stability testing with retained samples to meet regulatory and retailer requirements.

QA/QC Program

Speed & Format Flexibility

High-speed canning, bottling, and kegging with low-oxygen handling and on-line inspection.

Packaging LinesBuilt for Craft, Seltzer, FMB, and Non-Alcoholic Leaders

Category specialists for modern beverage portfolios with rigorous compliance.

Hard Seltzers

Crystal-clear bases, precise carbonation, and flavor integration for crisp, low-calorie profiles.

Craft Beer & Specialty

Consistent core styles and limited releases with meticulous temperature and yeast management.

Flavored Malt Beverages

Complex formulations for RTD cocktails and FMBs with rapid scale and compliant labeling support.

Non-Alcoholic Beverages

Dealcoholized options and functional sparkling beverages produced with the same QA rigor.

R&D & Pilot Runs

Pilot batching and sensory panels to validate flavors, mouthfeel, and stability before full-scale production.

Certified, Data-Driven, and Built for Speed

A single partner for formulation, production, packaging, and distribution—anchored by compliance and transparency.

- SQF Level 3, NSF, OU Kosher, and Organic-certified processes.

- Flexible run sizes from 5K to 500K cases with rapid changeovers.

- In-house lab for micro, sensory, shelf-life, and package integrity testing.

- Integrated warehousing and freight coordination for national retail distribution.

24/7

Live production visibility through MES dashboards.

50+

Quality checks per batch covering micro, sensory, and packaging.

5K–500K

Run size flexibility to support pilots through national scale.

Case Studies That Prove Commercial Readiness

Real programs delivered on time, on flavor, and on spec.

Hard Seltzer Launch

Accelerated formulation and packaging for a new regional seltzer brand with national retail ambitions.

Read Case Study

Craft Flagship Revamp

Stability and shelf-life improvements for a legacy craft portfolio without sacrificing flavor character.

Read Case Study

FMB Innovation

Co-created a new FMB line with rapid pilot batches, sensory panels, and compliant labeling support.

Read Case StudyEvery Product Backed by Industry-Leading Standards

KGM operates with layered compliance to meet retailer, regulatory, and brand requirements.

SQF Level 3

Comprehensive food safety and quality systems validated by third-party audits.

NSF & OU Kosher

Process controls for ingredient integrity and clean, compliant production.

Organic Capable

Certified pathways for organic and better-for-you beverage programs.

Full Traceability

Batch-to-shelf tracking with retained samples and digital audit trails.

Ready to Bring Your Beverage to Life?

Let's align on your formulation, format, timeline, and distribution plan.